Automated Optical Inspection (AOI) in Electrical Component Manufacturing: Making the Case for AI

Electrical component manufacturing is under relentless pressure to deliver higher quality, faster throughput, and greater reliability. As board complexity surges and tolerances tighten, conventional manual inspection struggles to keep pace. Automated Optical Inspection (AOI)—now increasingly powered by AI—offers a step-change in quality control that managers and directors cannot afford to overlook.

Automated Optical Inspection (AOI) with AI Is a Game Changer for Electronic Component Manufacturing.

What Is Automated Optical Inspection (AOI)?

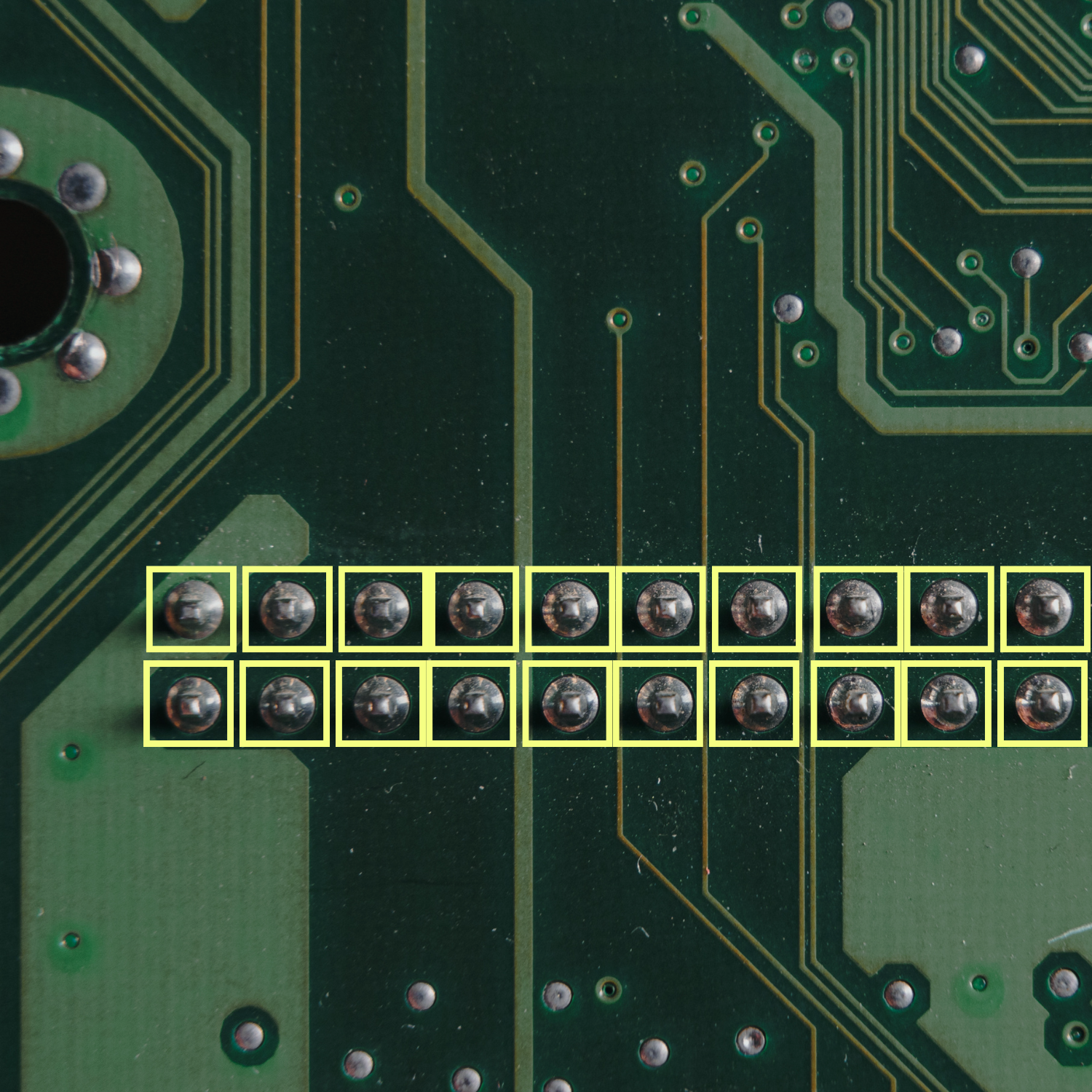

AOI is a machine-based inspection technology using high-resolution cameras and advanced software to analyze printed circuit boards (PCBs) and electrical assemblies for defects. The technology detects issues such as missing or misaligned components, soldering problems, surface scratches, and more—often at micrometer precision and high speed.

Why Automated Optical Inspection (AOI) Is a Game Changer

Automated Optical Inspection (AOI) brings a new level of precision and efficiency to electrical component manufacturing. By leveraging real-time defect detection, AOI systems catch problems during or right after assembly—stopping faulty parts before they escalate into costly rework or product failures.

These advanced systems can inspect hundreds or even thousands of circuit boards per hour, allowing manufacturers to consistently meet demand without bottlenecks. Unlike manual inspection—which is prone to fatigue and oversight—AOI delivers objective, repeatable quality control 24/7, continually learning and adapting to new defect types as designs evolve.

With comprehensive coverage of a wide range of defects and the ability to generate actionable, digital inspection records, AOI not only improves process optimization but also ensures easier compliance and audit readiness. By dramatically reducing rework, waste, and post-shipment recalls, AOI delivers significant cost savings—and a compelling business case for investment in modern, AI-driven manufacturing.

Key Benefits of AOI Implementation

1. Early Fault Detection and Process Optimization

AOI systems identify defects in real time—during or immediately after assembly—preventing faulty components from progressing and reducing the cost of downstream rework.

Early detection means problems are caught before they affect larger production batches, minimizing scrap and preventing costly field failures.

2. Enhanced Speed and Productivity

Automated systems inspect hundreds—sometimes thousands—of boards per hour, far outpacing manual inspection and scaling effortlessly with demand.

By removing production bottlenecks, AOI allows lines to operate at full throughput.

3. Consistent, Objective, and Reliable Inspection

Human inspectors can miss subtle defects, especially during long shifts or in high-volume settings. AOI delivers uniform, reproducible results 24/7, ensuring consistent quality across every product.

Sophisticated AI-driven AOI further reduces “false positives” and learns from new examples, optimizing parameters and adapting to changing designs.

4. Comprehensive Defect Coverage

AOI systems detect a broad range of faults, including solder bridges, insufficient/excess solder, component misplacement, missing parts, and surface anomalies such as scratches or contamination.

Advanced variants utilize 2D/3D imaging and machine learning to capture subtle or emerging defect types as designs evolve.

5. Data-Driven Quality and Process Improvement

Each inspection generates detailed digital records, enabling root cause analysis, process optimization, and continuous improvement across multiple sites and lines.

AOI data supports compliance with IPC and regulatory standards, and helps manufacturers demonstrate quality to clients and auditors.

6. Significant Cost Savings

By detecting and correcting errors early, AOI prevents expensive rework, reduces waste, and limits field returns or recalls. Studies indicate post-assembly defect repairs can cost up to 10 times more than in-process fixes.

Proven labor savings and higher productivity help justify initial investment over time.

Practical Implementation Considerations: AOI Benefits

Maximizing the value of Automated Optical Inspection (AOI) systems starts with understanding their core advantages and practical impact for managers and directors. Below are the key implementation benefits that make AOI a strategic investment in modern electronics manufacturing.

Early Defect Detection

Less rework, fewer defective escapes.Speed & Scalability

Higher throughput, no bottlenecks.Consistency & Reliability

Stable inspection quality, greater client trust.Data & Traceability

Supports ongoing improvement and easy audits.Cost Control

Lower labor, scrap, and recall costs.AI/ML Enhancement

Adapts quickly to new defects, fewer false rejects.

Real-World Outcomes

Defect detection accuracy rising to 98–99% vs. 85–90% in manual inspection, even at component speeds of 5,000+/hour.

Leading manufacturers report up to 40% fewer defects, 30% lower downtime, and measurable increases in yield and customer satisfaction after AOI implementation.

The Bottom Line for Decision Makers

Implementing Automated Optical Inspection is no longer just a question of catching up with best practices—it is a prerequisite for excellence and competitiveness in electrical component manufacturing. The compelling benefits in quality, speed, traceability, and cost make a strong business case, especially as AI-driven AOI continues to evolve, adapt, and deliver higher returns on investment.

For managers and directors, embracing AOI is an essential step toward digital transformation, resilient operations, and long-term profitability.

Ready to Transform Your Business with AI?

At Nordic Vision AI, we specialize in turning cutting-edge artificial intelligence into practical, high-impact solutions tailored for your business. Whether you’re looking to:

Improve quality control with automated inspections

Drive efficiency through predictive analytics

Enhance customer experiences with personalization

Or scale AI to new heights in your operations

Our team of experts is here to help you achieve measurable results—safely, responsibly, and at scale.

Take the next step toward smarter, more efficient, and competitive operations.

Let’s discuss how AI can power your growth.

Accelerate your digital transformation. Nordic Vision AI—turning vision into results.